You can move to the next element in the list of results using the tab key.

Using carbon fibres in concrete construction: Efficient reinforcement through automated production

Funding duration:

Start

01.10.21

End

31.05.24

The construction industry is responsible for a large proportion of global CO2 emissions, particularly through the production of concrete. More material is often used than is actually necessary for the load-bearing capacity of a structure. Traditional steel reinforcements lead to high weight and increased resource utilisation.

In addition, these are still mainly assembled and installed manually. There has hardly been any digitalisation and automation of processes in the construction industry to date.

Lightweight construction technologies, such as the use of carbon fibres, offer a more environmentally friendly solution here. On the one hand, these materials are lighter, more efficient and more durable than conventional metallic reinforcements and therefore enable resource savings in concrete consumption. Secondly, the processes for reinforcement production are to be automated in future. This will enable the efficient and cost-effective production of carbon fibre reinforcements for concrete components.

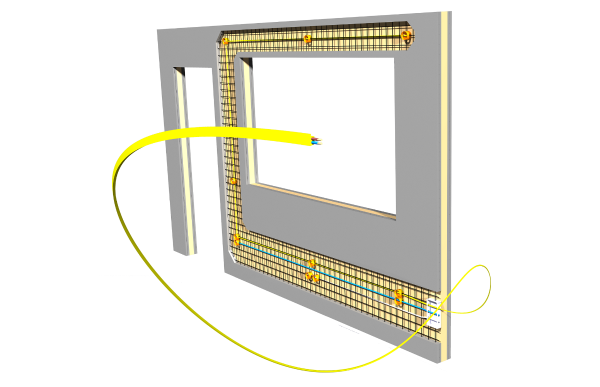

In the 3DHyBeBe research project, the project team aims to develop an automated manufacturing solution that enables the precise and cost-effective use of carbon fibres as reinforcement in concrete construction. The key to the solution lies in combining construction robotics and efficient production. Through the targeted, robot-assisted placement of the fibres, the researchers want to increase the load-bearing capacity of the concrete components and simultaneously optimise the use of materials.

The results of the research project should reduce the consumption of resources and significantly improve the carbon footprint of concrete components. A key challenge here is to create a solution that is scalable and economically feasible so that it can represent a sustainable alternative to conventional steel reinforcement in concrete construction.

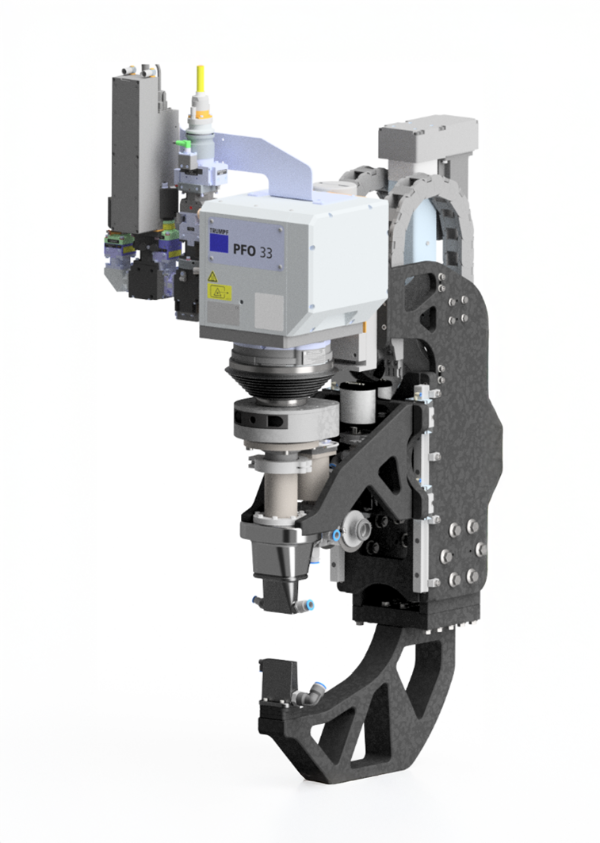

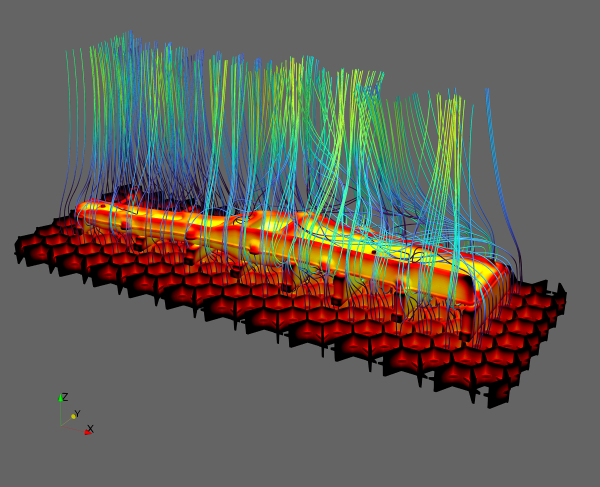

The research team is initially concentrating on developing an algorithm that determines the ideal course of the fibres depending on the structural requirements of the component. In this way, the carbon fibres are optimally designed to absorb tensile forces in the component. The researchers translate these calculations into control commands for a special production machine that enables the fibres to be precisely integrated into the concrete material. The prototype developed in the project includes a production line for the fibre reinforcement and an articulated arm robot for the automated implementation of the reinforcement structures.

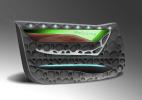

The basis for reinforcement production is the optimised composition of the materials. The project team combines carbon fibres with various matrices to ensure the bond to the concrete. On the one hand, the researchers are investigating a cement-based matrix for use in conventional, cement-based concretes. Secondly, a geopolymer matrix - a synthetic material that offers many advantages in terms of processing and high resistance to chemical influences. The aim is to improve the transmission of forces between the reinforcement and concrete.

The demonstrative production of reinforcement structures shows that the method reduces material consumption by around a third, while at the same time ensuring technical and economic feasibility.

Producing concrete walls in CO2-reduced lightweight construction: mobile 3D concrete printing robots

Funding duration:

Start

01.02.22

End

31.01.25

Processes in the construction industry have been little digitalised and automated to date. Standardised and inflexible processes often lead to inefficient use of materials, energy, time and labour. Resource-intensive concrete construction in particular causes considerable CO2 emissions. Additive manufacturing of concrete offers a solution that allows for specifically dimensioned cross-sections and significantly simplifies logistics on construction sites. Automation, digitalisation and new material approaches are considered together.

In the 3DLight_OnSite project, researchers are developing an innovative concept for 3D concrete printing. The aim of the project partners is to use individually movable printing robots to produce structural-optimised concrete walls in CO2-reduced lightweight construction, thus combining sustainability, construction robotics and efficient production. In order to make optimum use of the economic and ecological potential of concrete printing, they are relying on end-to-end digitalised and highly automated production.

The results of the research project should make it possible for mobile robot fleets to move flexibly around the construction site in future and print the concrete elements directly on site. In contrast to stationary printing systems, which are less flexible and less scalable, this will enable faster, more cost-effective and more environmentally friendly additive manufacturing.

The prototype developed by the project participants includes a crawler chassis and an industrial robot with a special nozzle head for the 3D printing process. The researchers are digitising the entire planning and production process in order to optimise the use of the robots. All relevant construction data is modelled digitally and transferred directly to the robots. Digitalised production methods also offer advantages beyond the construction process. For example, building materials can be tracked and components can be sustainably dismantled and reused in the sense of "urban mining".

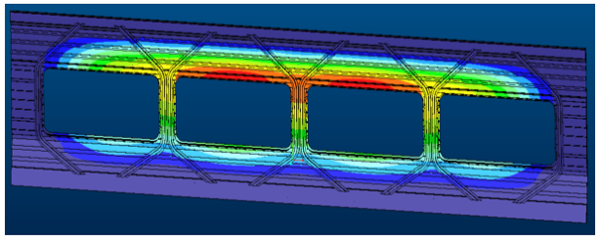

The researchers are also focussing on material savings through a lightweight construction method inspired by nature. For example, CO2-intensive, high-strength concretes are only to be used where they are structurally necessary. To this end, the project participants are using structures similar to honeycombs, which offer maximum stability with minimum material consumption. For example, the wall shell of a building is constructed from pressurised mortar and then filled with foam concrete, which serves as insulation and soundproofing. This construction method significantly reduces material consumption and CO2 emissions. The project partners are also endeavouring to develop more environmentally friendly concrete mixtures.

Produce aerogels cost-effectively: Innovative system for lightweight concrete and plaster

Funding duration:

Start

01.04.21

End

31.12.24

In order to drive forward the energy transition and achieve the EU's climate protection targets, energy and resources must be saved. 75 per cent of all buildings in the EU are not energy-efficient by today's standards. At the same time, there is currently a lack of flexible, functional and cost-effective materials for thermal insulation in the construction sector.

Aerogels are porous solids in which the majority of the volume consists of pores. The fine structure of the aerogel firmly traps air molecules, resulting in a unique insulating effect. The nanopores in the aerogel restrict the heat-conducting air molecules so much in their freedom of movement that no energy is passed on to other air molecules. This turns the aerogel into a high-performance insulator with very low thermal conductivity, which leads to greater energy efficiency during the utilisation phase of the building or product fitted with it. The mineral insulating materials do not require any petroleum-based raw materials.

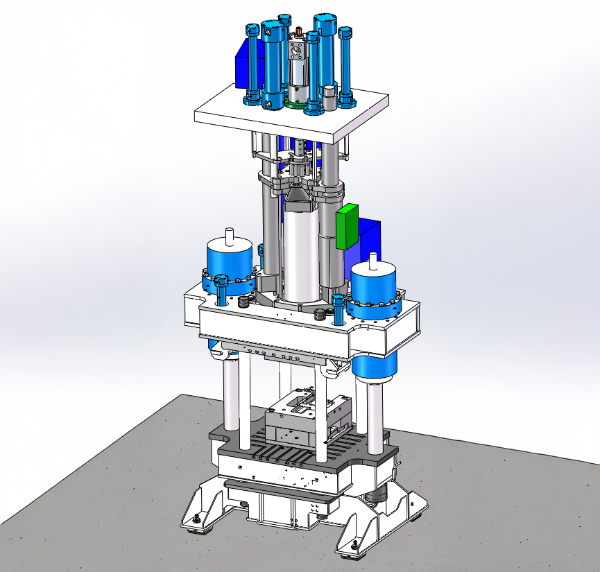

The project team is developing an innovative and sustainable system for insulating plaster and lightweight concrete that creates completely new possibilities. The aim is to develop a cost-effective manufacturing process for aerogels and new formulations. Aerogels are to be utilised in various applications in the field of thermal insulation systems, lightweight concrete and sandwich elements for façades and roof elements. The researchers are further developing the existing pilot plant for aerogels in order to transfer the process to an industrial scale, taking economic aspects into account, and thus make it economically competitive in the mass market for thermal insulation.

The researchers are investigating the entire value chain, from material selection and production to processes and system customisation. The centrepiece of the work is the expansion of the existing plant to include additional pump technology. In addition, separators are planned to enable the recovery of the individual fluids, in particular the solvent, in order to make the process more economical.

The result is a new type of production process for aerogels that combines various production steps. Manufacturing costs are reduced by half. Production is reduced from more than ten hours to just four hours and does not require any environmentally hazardous chemicals. The process has been successfully trialled on a small scale and the next step is to transfer it to an industrial scale.

Reducing the weight of agricultural machinery: lightweight, functionally integrated carbon chassis

Funding duration:

Start

01.06.21

Today

09.03.25

End

31.05.25

The performance of agricultural harvesters has risen sharply in recent decades. At the same time, machines are getting bigger and heavier, which presents manufacturers with various challenges. On the one hand, the high weight leads to increased soil compaction, which worsens the living conditions for soil organisms and restricts root growth and water absorption. As a result, the fertility and yield of agricultural land decreases. On the other hand, the heavier and larger machines lead to problems in complying with road traffic regulations.

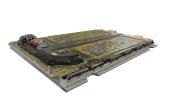

The AGRILIGHT team aims to significantly reduce the weight of the harvesters through the use of innovative lightweight construction concepts. They are developing a functionally integrated lightweight structure made of glass fibre and carbon fibre composites to replace the central steel frame of the machines and integrate adjacent components - such as tanks - into the component. This change is intended to reduce fuel consumption and CO2 emissions while minimising soil compaction. In addition to the ecological improvement, the researchers would also like to simplify the road traffic authorisation of the machines thanks to the reduced weight.

To further reduce assembly times and costs, the team is developing new approaches to structural hybridisation for the particularly stressed interfaces of the machines. The aim is to be able to retain existing joining methods from metal processing for lightweight, fibre-reinforced materials.

At the start of the project, the team analysed the existing steel structure and the adjacent functional units of the harvester. It then developed the new functionally integrated frame structure made of fibre-reinforced plastics (GRP/CFRP), taking into account the specific mechanical, electrical and chemical properties of these materials.

For structural hybridisation, the team uses multi-layer insert technology, in which metallic inserts are integrated into the fibre composite during production. This means that existing joining methods from metal processing can be retained and downstream work steps such as drilling and gluing can be omitted, which significantly simplifies assembly.

At the end of the project, the new frame structure will undergo extensive mechanical testing to assess its suitability for series production. To do this, the team integrates the prototype into a realistic test setup and tests the frame on a special test bench to simulate real-life operating conditions. In this way, the team ensures that the new structure remains intact over the entire service life of the machine.

The developed prototype will be presented for the first time at Hannover Messe 2024 and shows a weight reduction of over 430 kg compared to the conventional steel frame construction. The project has been recognised as a finalist for the prestigious JEC Innovation Award in the Equipment Machinery & Heavy Industries category.

Finding optimal building materials: concrete construction with AI and 3D printing

Funding duration:

Start

01.06.22

Today

09.03.25

End

31.05.25

The construction industry is one of the world's largest consumers of raw materials and energy and generates large amounts of waste. A large proportion of global greenhouse gas emissions are also generated during the construction, demolition and disposal of buildings. In particular, the production of concrete - one of the most frequently used building materials - with its main component cement causes considerable CO2 emissions.

The aim of the scientists in the AIBetOn3D project is to reduce the environmental impact of the construction sector. To this end, they are asking themselves the overarching question of how 3D printing can be used in concrete construction to minimise CO2 emissions without compromising the quality of the construction products.

On the one hand, the researchers are developing simulation models for 3D printers with the support of artificial intelligence (AI), which should help to identify optimal building materials and combinations of building materials by enabling reliable predictions of material behaviour and potential CO2 savings. The researchers are also working on an innovative 3D printer for building materials and the associated software.

As a concrete application, the researchers are looking at drainage channels and inlet boxes, which are to be implemented in different variants - in 3D concrete printing, combined 3D printing with concrete and plastic moulds and clay-based 3D printing. In addition to geometric parameters, material modifications are also being investigated.

They are developing a concept for a semantically causally correlated material production library. The AI-based algorithms and models developed are thus designed to understand the meaning of the data, analyse their relationships and recognise and use the causal relationships to enable precise predictions and optimisations. The library will contain information on novel, additively manufactured building materials and serve as a learning system to perform optimisation in terms of component dimensions, material composition and CO2 life cycle analysis. In addition, the researchers are testing the practical suitability of the developed printer and the associated software based on the specific use case.

Antistatic pipes for aviation: composite materials replace metal

Funding duration:

Start

01.06.21

End

30.06.24

In aviation, pipework systems for fuel, hydraulics and ventilation are essential. Currently, they are mostly made of metal, which leads to high weight and limited design freedom. Composite materials offer great potential here: they are lighter, corrosion-resistant and allow greater design freedom.

However, they do not yet fulfil all requirements, particularly with regard to electrical conductivity and the economical production of complex pipe geometries. Previous solutions have reached their limits when it comes to combining functionality, safety and efficiency. This is where the AntiStatic research project comes in and searches for a new technological solution.

The project team wants to develop antistatic cable systems made of composite materials that can replace conventional metal pipes. The innovation lies in the combination of low weight, high mechanical stability and electrical conductivity. The pipes are to include both straight and curved sections and fulfil specific requirements of the aviation industry.

The focus is on resource-saving production and a modular design of the piping system. By using this technology, weight savings of up to 50 per cent could be achieved, thereby significantly reducing CO2 emissions in aviation.

The project team has combined the manufacturing processes of braided pultrusion and braided RTM (resin transfer moulding). Braid pultrusion is used to produce straight tubes that are particularly stable and lightweight thanks to continuous production. The braided RTM process is used for bent pipe sections, which allows the production of complex geometries.

The researchers have also developed a resin system that is filled with carbon nanotubes (CNT). This gives the components their antistatic properties without compromising their mechanical characteristics. The team then joined the individual tube segments together using a modular joining process. The researchers are now using a demonstrator to prove the practicality and efficiency of the developed technology.

Automated production of sandwich components: Robots increase efficiency and sustainability

Funding duration:

Start

01.01.22

End

31.12.24

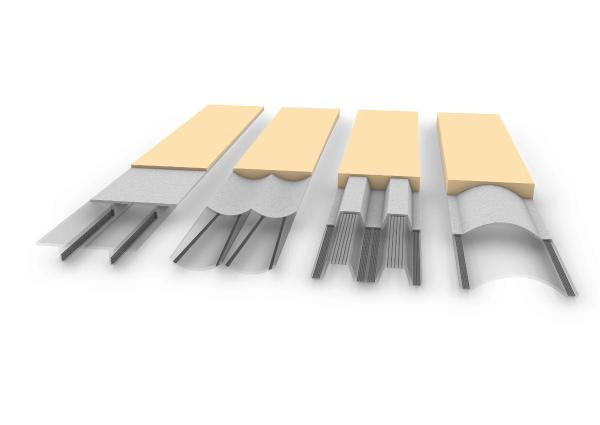

Composite sandwich structures are components made up of several materials with different properties. The combination of a strong inner layer, a lightweight support material and an outer layer makes them stronger than the individual materials and offers high strength with low weight.

Until now, however, the production of these sandwich structures has been complex and required a lot of manual work, which is why the sandwich construction method is mainly used for prototypes and small series. In order to expand the use of composite sandwich structures to other areas of application, the production of the components must be more automated.

In the APART project, the project partners are developing a fully automated production system for high-strength and lightweight sandwich components. A special feature of the system is the use of renewable raw materials such as cherry trees or sisal for the support layer. In this way, the team aims to create a CO2-reducing, sustainable process that is suitable for the series production of composite sandwich structures.

In addition to significantly shortening the production time of the components, automation should also increase production quality and reduce waste. This not only increases efficiency in production, but also promotes lightweight construction in areas where the sandwich construction method could not previously be used due to the high manual effort involved.

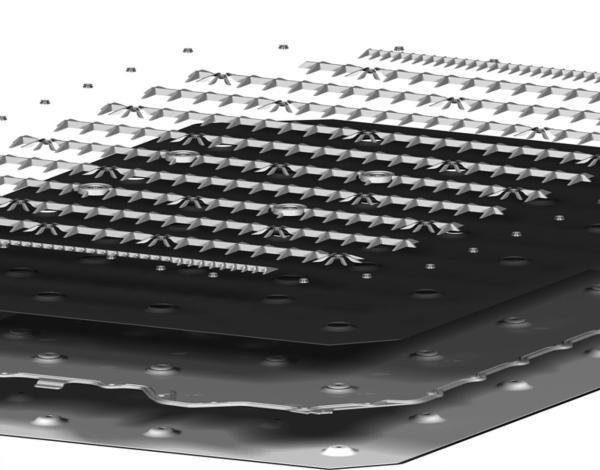

The researchers are developing a robotic system that automates several steps in sandwich production, including cutting, feeding and placing the bio-chips for the support layer. The bio-chips are produced in different shapes and sizes, for example from balsa, kiri wood or sisal fibers in combination with a bio-glue. A four-axis gantry system, equipped with sensors for image processing and ultrasound technology, takes over the precise placement of the bio-chips. The gantry system detects inhomogeneous biochips and sorts out faulty pieces to optimize quality and strength.

In order to test the practical suitability of the system, the project partners are testing the technology in the application fields of vacuum and hot pressing and are incorporating the results into the fine-tuning of the process. By optimizing the production steps in this way, they are developing a technology that is suitable for series production.

Sustainable wood fibre sandwich: industrial production and cross-sector use

Funding duration:

Start

01.11.20

End

31.01.23

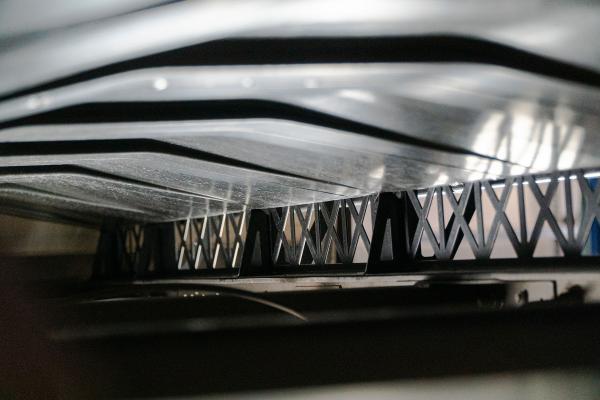

The team in the BENHoLei research project has set itself the goal of developing sustainable lightweight construction elements made from wood fibre materials across all sectors. The basis was the wood fibre material Homawave, which is characterised by its wave-like structure that is reminiscent of corrugated cardboard. This structure is produced by a continuous forming process in which wood fibre boards are corrugated and then combined with cover layers such as aluminium or high-density fibreboard. The result is stable sandwich materials that are more resource-efficient and considerably lighter than conventional wood-based materials. BENHoLei has shown that these materials can be used in a variety of ways, for example in furniture, vehicle parts or the packaging industry, and can make an important contribution to reducing CO2 emissions by reducing material consumption and weight.

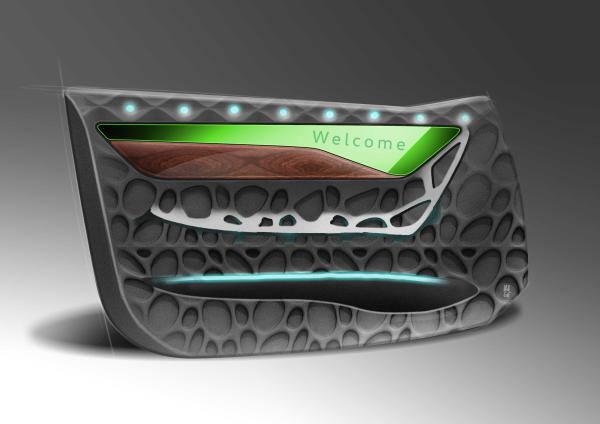

The aim of the researchers is to optimise wood fibre materials for large-scale production and thus enable more sustainable and environmentally friendly industrial processes. To this end, they are developing automated production processes that integrate mechanical testing and non-destructive testing methods. The focus is on improving material properties, such as flexural strength and dimensional stability, through hybrid combinations of cover and core materials. In addition to technical development, the project team is pursuing the goal of transferring the research results directly into practical applications. The use of Homawave in the furniture and automotive industries as well as in ship interiors should create both ecological and economic benefits such as lower material consumption, lower transport costs and a sustainable value chain.

The researchers successfully complete the material and process development. They further develop the Homawave core in combination with various cover layers and subject it to extensive mechanical tests. In particular, the successful tests with acrylate and phenolic resin systems lead to a higher forming quality and improved surface quality. At the same time, the team develops new roller geometries and optimises the production processes, for example through more precise temperature and humidity settings, thereby increasing the production speed to up to 5 metres per minute. They integrate non-destructive testing methods into the process chain to ensure quality and detect defects at an early stage.

The sandwich materials developed in the project are tested for their practical suitability using a lectern as a demonstrator. The positive response, for example at the INTERZUM 2023 trade fair for suppliers to the furniture and interior design industry, confirms the market relevance of the materials. Finally, the scientists are developing a concept for a production plant suitable for large-scale production that fulfils both economic and ecological requirements.

Making the process chain for lightweight products more sustainable: based on bionics and AI

Funding duration:

Start

01.07.21

End

30.06.24

Lightweight construction is a key technology for curbing global warming and increasing economic performance at the same time. In the mobility sector in particular, companies can save material and therefore resources thanks to lightweight construction. At the same time, lightweight vehicles emit less CO2 during operation. However, the manufacturing and recycling processes for vehicles are often emission-intensive. There is a lack of holistic solutions that make products more sustainable over their entire life cycle and optimise them along the vertical and horizontal process chain.

The project partners want to make the entire process chain for lightweight products more sustainable and increase resource efficiency across the entire life cycle. To this end, they are optimising the CO2 footprint and the use of resources in the manufacturing process. The researchers are working on new development concepts in order to be able to take these aspects into account during the planning and design of individual components or complex building structures. They use methods of automation, artificial intelligence (AI) and bionics, i.e. the transfer of natural phenomena and principles to technology, as the basis for new algorithms and assistance services.

The researchers are supplementing established processes such as the computer-aided design of components (CAD designs) with additional elements. To this end, they are developing design algorithms inspired by biology. AI-based assistance services should take into account and integrate the downstream life phases as early as the product creation stage and predict simulation results. The project team is developing a semi-automated design process that enables products to be adapted and optimised quickly without having to carry out extensive new development. This not only saves time, but is also sustainable. This is because manufacturing processes and materials that are only economical and sustainable in the introductory phase of a product, for example, can be replaced quickly and easily in later phases of the product life cycle.

Sustainable braking system: reducing particulate matter and enabling circularity

Funding duration:

Start

01.09.21

Today

09.03.25

End

30.06.25

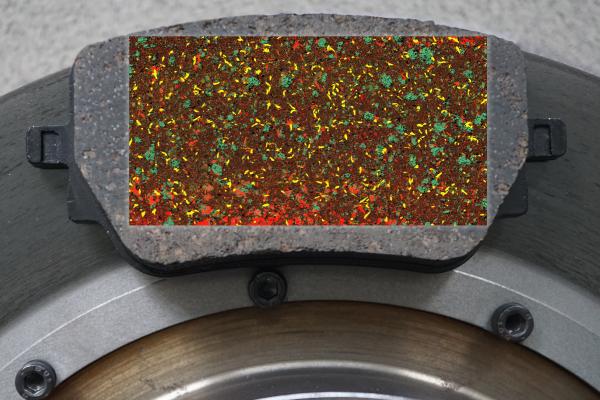

Urban road traffic releases large amounts of particulate matter, which can pose significant health risks. Around half of the particulate matter is caused by brake abrasion – regardless of the drive system of the vehicle. Due to their small size, about 90 percent of these particles enter deep into the respiratory tract and can cause serious damage.

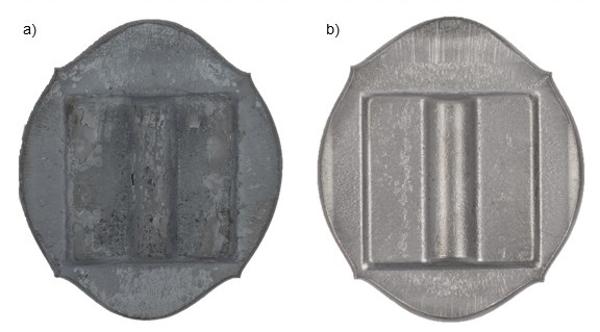

The main problem lies in the braking systems currently in use: these are mostly made of gray cast iron alloys and matching brake linings. During braking, the materials wear down and the released particles enter the air. There are currently no alternatives to traditional braking materials for the series production market.

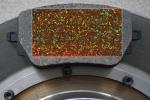

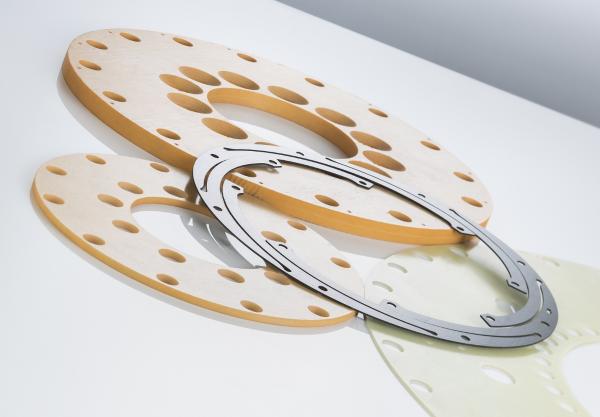

The project team aims to develop a cost-effective, low-wear, low-emission and recyclable braking system for industrial production. To this end, the researchers are using brake discs made of highly hard-material particle-reinforced aluminum matrix composites (AMC, short for: aluminum matrix composites). AMC brake discs are almost wear-free in combination with suitable brake pads, so that hardly any particulate matter is produced. This significantly improves air quality, especially in cities and at traffic junctions.

In addition, AMC braking systems are lightweight constructions, which in turn reduces CO2 emissions while driving. Unlike conventional gray cast iron brake discs, AMC brake discs are also recyclable and reusable.

One of the biggest challenges for the use of AMC brake systems is the development of suitable brake pads. These must be designed in such a way that a so-called tribofilm forms during braking. This is created by chemical reactions and acts like a protective layer that prevents wear and the formation of fine dust.

In order to develop suitable brake pads, the project team is therefore analysing the surface structure of the materials using electron and 3D scanning microscopes. Conventional brake pads consist of up to 30 individual components.

The team is optimising these parts, particularly with regard to friction coefficient, durability and noise development. The researchers are also replacing questionable materials, such as copper alloys, with more environmentally friendly alternatives that also support the formation of the tribofilm.

Replacing heavy concrete ceilings: prefabricated ceiling elements made of carbon concrete

Funding duration:

Start

01.03.23

Today

09.03.25

End

28.02.26

Concrete is the most widely used building material in the world. Large quantities of greenhouse gases are emitted, particularly during the production of cement, which forms the basis for the manufacture of concrete. Cement production is responsible for around 8 per cent of global CO2 emissions. It is therefore crucial for the transformation of the construction sector to reduce cement consumption in particular. One option is to gradually replace steel with pre-stressed carbon fibre reinforcement. This leads to an increase in material and energy efficiency, as it creates lean, mass-reduced and therefore resource-saving structures. A particularly interesting area of application is the use of carbon concrete in the area of floor slabs, for which large quantities of reinforced concrete are used in conventional construction methods.

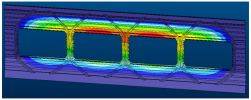

The project partners want to replace the 30 cm thick concrete ceilings usually used in solid construction with lightweight, non-corrosive load-bearing structures. To do this, they are using concrete elements pre-stressed with carbon, the cross-section of which they are reducing to a maximum of 10 cm. The researchers are focussing on prefabricated ceiling elements. These are particularly sustainable, as less waste is produced during manufacture, they are easier to dismantle and can be reused more easily. The carbon pre-stressed ceiling systems should fulfil all structural, fire, thermal and sound insulation requirements and at the same time be practicable.

These sustainable ceilings are developed and tested using a multidisciplinary approach. This includes developing the manufacturing methods, including the plant technology, as well as forecasting and validating the quality of the ceilings. In a comprehensive test programme, the carbon concrete components are tested for their load-bearing and deformation behaviour under short and long-term effects. This includes airborne and impact sound insulation as well as fire protection. The test results are used to validate the numerical calculation models that are used in all disciplines and with which the various parameters are optimised as a whole. The dimensioning of the component cross-sections, including the fasteners and supports, is carried out in accordance with applicable standards as part of the structural analyses. In addition to the small-scale tests, real-scale models are built and tested.

Saving resources in concrete construction: new concepts for large-format carbon fibre reinforcement

Funding duration:

Start

01.11.20

End

30.04.24

Concrete is currently the most widely used building material in the world. However, its production causes high greenhouse gas (GHG) emissions. To increase the load-bearing capacity of concrete components, so-called reinforcement is inserted into the concrete. This usually consists of steel mats, rods or mesh, which require a thick concrete cover due to their susceptibility to corrosion and therefore cause high GHG emissions.

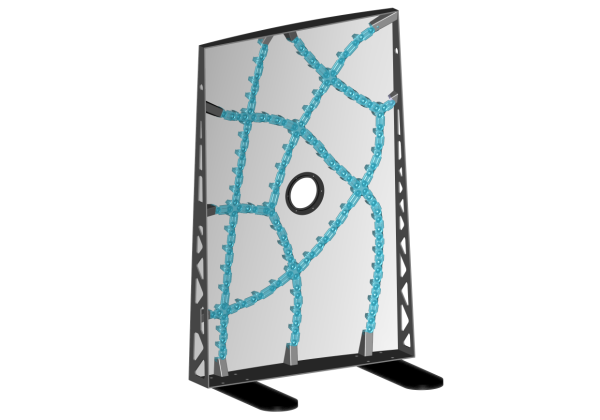

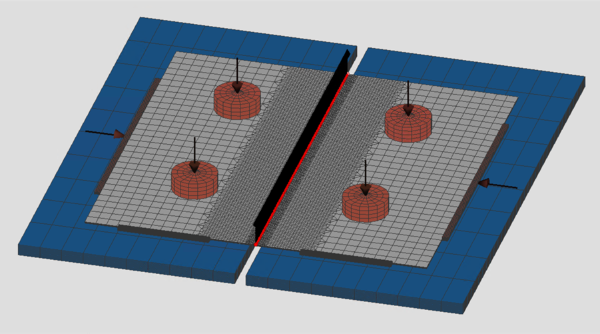

Carbon fibres, on the other hand, are six times more effective than steel and are not susceptible to corrosion. The use of carbon fibres instead of steel can therefore significantly reduce the amount of reinforcement and concrete required. However, different load cases have so far been considered separately when designing steel and carbon fibre reinforcement. This can lead to over-reinforcement and thus to an increased use of resources.

The project partners want to develop innovative, large-format carbon reinforcements for concrete construction and optimise them for industrial application. These carbon structures should be force-flow-compatible and particularly durable, resulting in resource-saving concrete components. To achieve this, they want to combine design and construction principles from lightweight construction with those of conventional concrete construction. This would also reduce GHG emissions during production and release them into the environment. The project partners anticipate a GHG savings potential of 86 per cent in the area of building construction compared to conventional reinforced concrete construction.

The team no longer installs individual reinforcements for the different load cases, but an optimised and self-contained reinforcement structure. As a result, three-dimensional structures can be created that optimally adapt to the flow of forces and are therefore highly effective and resource-saving. The reinforcements can then be cast with a lower concrete cover. This allows significant material savings to be made on both the concrete and the reinforcement.

Thanks to its cross-technology composition, the team can cover the entire value chain. The researchers are optimising the geometry and mechanical properties of the new type of reinforcement structure and adapting the production process accordingly. They are developing a process for the production of impregnated and wrapped fibre strands that enables a very high utilisation of the fibre tensile strength in the strands by optimising the alignment of the individual fibres. The mechanical properties of the reinforcement within concrete components can also be optimally utilised by optimising the strand arrangement within the reinforcement cages on a test basis.

Reducing the CO2 footprint of cars: hybrid components made of aluminium and steel

Funding duration:

Start

01.03.21

End

31.08.24

Road traffic in Germany causes around 160 million tonnes of CO2 every year and is therefore responsible for around 20 percent of the country's total CO2 emissions. One effective method of reducing the CO2 emissions caused by cars is to reduce vehicle weight through functional lightweight construction. Three technologies in particular are currently being used for this purpose: High-strength aluminium alloys, aluminium-steel mixed construction and Tailor Welded Blanks (TWB) - welded body parts made of steel sheets with different strengths and thicknesses.

The researchers in the CO2-HyChain project aim to combine these technologies in order to further reduce vehicle weight. In particular, high-strength aluminium TWBs and hybrid aluminium-steel TWBs are to be used. By using aluminium and steel together, the participants want to combine the positive properties of the two materials - in particular the high strength of steel and the low weight of aluminium.

The project partners want to transfer the solutions researched on a laboratory scale to industrial production through technology transfer and further develop the entire value chain. The introduction of these technologies should reduce the CO2 footprint of passenger cars by up to 15 per cent.

The researchers are developing new welding methods and heat treatment techniques to economically produce high-strength aluminium-steel joints with different sheet thicknesses. They also want to significantly improve the mechanical properties and durability of the weld seams, which will significantly expand the industrial applications of high-strength aluminium and hybrid aluminium-steel TWB.

In order to integrate these technologies into existing production processes and make production more economically and ecologically sustainable, the project partners are developing highly efficient production systems for the manufacture of large-format aluminium-steel TWB and tailor-welded coils (TWC) - coils made from metal strips of different materials or thicknesses. They develop control and regulation concepts to enable reliable process control and ensure sufficient quality of the TWB and TWC. They also focus on the development and implementation of new recycling concepts in order to further maximise resource efficiency.

Optimising battery housings for e-cars: with aluminium foam and more efficient production

Funding duration:

Start

01.05.21

End

31.10.24

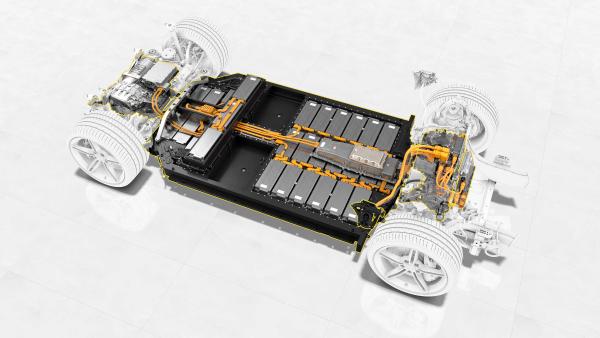

Electric cars can help to reduce greenhouse gas emissions in the transport sector and protect the climate. The battery system is the centrepiece of modern electric cars and a central component for sustainable mobility. With innovative design principles, materials and production processes, lightweight construction can help to make battery systems lighter, optimise their properties in use and make their production more efficient.

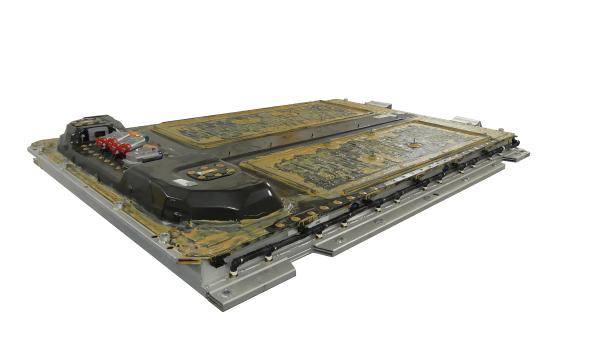

The aim of the COOLBat research project is to increase the range of electric cars by reducing the weight of the battery housing. At the same time, the researchers want to improve the performance of the batteries and enable faster charging times. In addition, the project team is investigating how the production of battery housings can be made significantly more efficient using lightweight construction approaches in order to reduce CO2 emissions during production.

The battery system of an electric car being analysed serves as a reference and demonstrator for the researchers. The research results will then serve as a blueprint for the development, optimisation and scaling of specific lightweight materials and technologies for other industries and applications, such as trains, aircraft and ships or food and medical transport.

The researchers are scrutinising all development steps to see how they can contribute to CO2 savings and sequestration. To do this, they look at the entire battery system. In addition to the battery module with its cells, this includes the housing with structures for load distribution and temperature control. These include frames, covers and base plates, which protect the batteries from overheating and damage.

The team combines individual systems in order to integrate more functions in a smaller space and with fewer interfaces. The aim is to combine thermal and mechanical tasks. In future, support structures will contain directly moulded-in temperature control channels. In the floor panels, for example, the function of the cooling unit will be combined with that of crash protection in a single component.

The use of aluminium foam enables optimum load distribution and energy absorption in the event of an accident. The foam is combined with a so-called phase change material that can store heat and cold energy and release it again as required. This combination of materials also reduces the amount of energy required to cool the battery. The cover of the battery housing is designed in such a way that the housing can optimally absorb the loads acting on it. In addition, the participants are developing new heat-conducting materials to replace more expensive and environmentally harmful heat-conducting pastes. The lightweight construction solutions used should save 15 per cent CO2 per battery housing.

Producing washing machines more sustainably: Material recycling and digital simulation

Funding duration:

Start

01.01.22

End

31.12.24

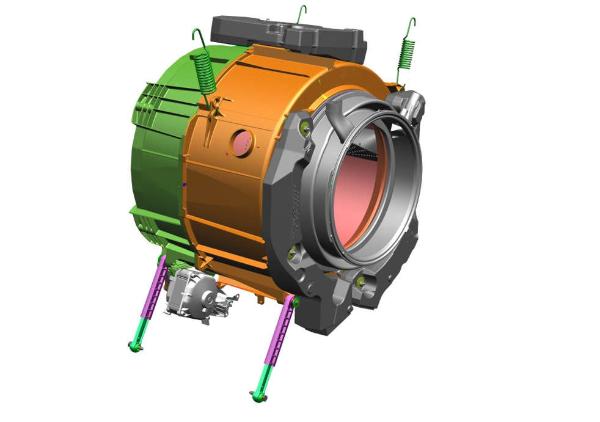

The drums of washing machines spin in almost every German household. It is therefore important that the appliances are not only as energy-efficient as possible in use, but also in their production. This is where the researchers in the DigiLaugBeh project come in, using digital simulations to transfer innovative lightweight construction solutions from automotive engineering to the washing machine application. The lye containers are manufactured using an injection moulding process. A machine plasticises the plastic used - short fibre-reinforced thermoplastic - and injects the softened material into shape under pressure.

The project partners want to use the lye container that surrounds the washing drum to show how great the potential is to save CO2 and recycle materials. To do this, they are using innovative lightweight construction solutions. The researchers are creating a digital twin in order to visualise the entire product development chain, simulate the entire component design and take a holistic view of the process, material and environmental balance. Ultimately, the project team wants to produce a demonstrator that combines all the knowledge gained and thus enables the transition to serial production of the innovative lye container.

The project partners are using digital simulations to optimise the entire manufacturing process. For example, they want to use long glass fibres instead of the short fibre-reinforced material. They are also replacing conventional injection moulding with thermoplastic foam injection moulding. In this process, the molten plastic is charged with carbon dioxide or nitrogen and then foamed. This protects the fibres and reduces the risk of component distortion.

The approaches used are analysed for their life cycle right from the start. The researchers assess the respective CO2 footprint and optimise it. They also aim to replace around 50 per cent of the materials used with recycled materials, for example by recycling returns at the end of their service life.

The researchers assume that this will save 30 to 40 per cent of CO2 equivalents per kilogramme of material used. The lye container weighs around 4 kilograms. With 8 million parts produced annually, replacing half of the materials used with recycled material would save 19 to 25 thousand tonnes of CO2 equivalents per year.

Producing modular, recyclable components: Lightweight structures made of composite plastic

Funding duration:

Start

01.10.23

Today

09.03.25

End

30.09.26

In view of increasing climate and environmental pollution as well as EU-wide climate protection initiatives and national CO2 reduction targets, the need for recyclable, resource-saving lightweight construction solutions is increasing across all industries. While large structures in the mobility and energy sectors - for example in the construction of vehicles or wind turbines - have primarily used steel and aluminium to date, new material approaches are needed to meet the new requirements for sustainability and recyclability. Fibre-reinforced plastics (FRP) offer a resource-saving alternative here. However, conventional thermoset FRPs, i.e. fibre-reinforced plastics that take on a permanent and unchangeable shape after hardening, are difficult to recycle and make repairs and dismantling more difficult. Thermoplastic fibre-reinforced composites, which can be melted and welded, offer a solution that enables greater recyclability and more flexible use.

The central aim of the DOM4Composites project is to develop large, modular structures made of thermoplastic FRP for the mobility and energy sectors. The innovative lightweight structures are to be used in ships, rail and commercial vehicles and wind turbines, for example. The scientists want to set technological standards for more environmentally friendly production of large structures.

The researchers are already considering a disassembly-optimised design at the design stage in order to be able to recycle the materials better and increase material and energy efficiency. Thanks to the modular design, they also want to simplify the repair of individual modules, which can increase the service life of entire assemblies. Thanks to the innovative design, materials could be reused several times, the weight of the structures could be significantly reduced and CO2 could be saved during production and utilisation.

The team develops scalable manufacturing processes for thermoplastic FRP. They use innovative joining and disassembly concepts to enable modular construction and subsequent recycling of the components. To this end, the researchers first define comprehensive requirements for mechanical and thermal loads as well as quality criteria for the materials for various applications.

A particular focus of the scientists is on the development of recurring substructures that allow the efficient and economical realisation of modular lightweight structures. To this end, they adapt the materials for their suitability in comprehensive material tests. To join the components, the team uses various joining techniques such as adhesive bonding, resistance welding and hybrid joining to ensure recyclability and ease of repair.

The project partners are testing the approaches developed on two cross-sector prototypes, a ship's hatch cover and the side wall of a railway vehicle body. With an accompanying life cycle analysis, the team is evaluating the ecological impact of the entire process chain in order to further optimise the environmental balance and demonstrate the potential of sustainable lightweight structures in practice.

More durable components: Hybridisation makes fibre composites more resilient

Funding duration:

Start

01.01.21

End

30.06.23

Fibre-reinforced plastics (FRP) have established themselves as key materials in lightweight construction as they offer many advantages for various applications thanks to their mechanical properties and low specific weight. They are replacing metallic materials, particularly in the mobility and mechanical engineering sectors, where components have to withstand high dynamic loads. However, conventional FRP materials reach their limits when it comes to fatigue strength and service life. Material fatigue under dynamic loads often leads to shortened life cycles and increased failure rates, resulting in higher costs and a larger CO2 footprint. To counteract this, the hybridisation of FRP is being investigated: The combination of different fibre types in one material makes it possible to specifically improve the properties. However, to date there has been a lack of standardised semi-finished products and application-ready methods - this is where the DurableHybrid research project comes in.

The project team has set itself the goal of increasing the fatigue strength of dynamically loaded FRP components by 30 percent through hybridisation. Hybridisation is intended to improve the material properties without increasing the weight. These improvements should help to significantly reduce the carbon footprint of the components, as more durable materials need to be replaced less frequently, thereby reducing material consumption and emissions. The focus is on components subject to bending loads, such as leaf springs, which are used in numerous industries. In the long term, the scientists are aiming to provide standardised semi-finished products for hybrid FRPs. In this way, they want to enable companies to produce more durable and resource-efficient components cost-effectively.

The project team combines experimental research and simulation to develop hybrid FRPs. First, the researchers are investigating how different types of fibres can be combined in one material in order to achieve optimum material properties. They carry out tests to show how loads affect fatigue strength. At the same time, they are developing digital simulation models that precisely map the properties of the hybrid materials and facilitate the design process. The team uses the knowledge gained in this way to produce leaf spring prototypes and test them in real applications. The results are incorporated into a digital modular system that is intended to provide standardised recommendations for the use of hybrid materials in design.

Developing natural fibre-reinforced plastic components: with innovative 3D printing

Funding duration:

Start

01.05.21

End

30.04.24

Land vehicles consist of large and heavy components that are difficult to recycle. To make them lighter and more sustainable, lightweight, natural fibre-reinforced plastic components could replace the metal structures used today. These renewable raw materials are not only sustainable, but also have a lower density, better acoustic and mechanical damping and are biodegradable. Above all, their production consumes less energy and therefore emits significantly less CO2. Natural fibre-reinforced plastics are therefore particularly attractive for lightweight construction in mobile applications.

The project team wants to develop the new lightweight components for a wide range of industries and applications: special vehicle seats - for example a lightweight seat for use in electric vehicles and special vehicles - tractor crossovers or attachments for pick-ups. The researchers are pursuing a holistic approach. They not only want to make the components lighter with environmentally friendly materials, but also consider the entire life cycle: how can the utilisation cycle of the components, from material selection and production to use and recycling, become more sustainable?

The researchers use the high-speed additive process SEAM (Screw Extrusion Additive Manufacturing). This innovative 3D printing process is eight times faster than conventional 3D printing. Thanks to the free shaping, even complex parts can be created. In addition, several conventionally manufactured individual components can be replaced by one additively manufactured part. The advantages: Digitalisation ensures shorter process chains and therefore faster production, the use of materials is as low as possible and manufacturers can produce many different individual pieces cost-effectively.

The team also uses natural fibre-reinforced plastics. The challenge with natural fibres is their ability to absorb moisture. The researchers want to solve this by means of an innovative pre-treatment of the fibres. The aim is not only to make the fibres water-repellent (hydrophobic) on the surface, but also on the inside to prevent them from penetrating the naturally occurring cavities and gaps.

The researchers are also carrying out ecological assessments of the individual fields of application over the entire life cycle. This enables them to demonstrate and further optimise CO2 and resource savings right from the start. The partners are also laying the foundations for the transfer to industrial production, for example by further developing and testing the SEAM process through specific applications with industrial partners.

Produce fibre tapes efficiently and sustainably: endless production with inline splicing

Funding duration:

Start

01.02.21

End

31.01.24

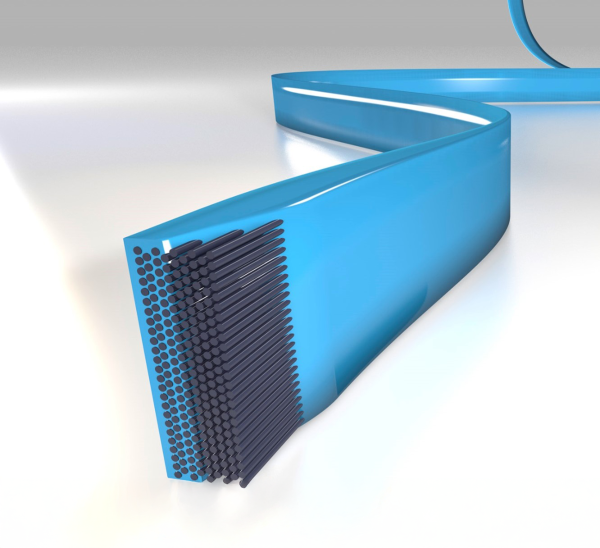

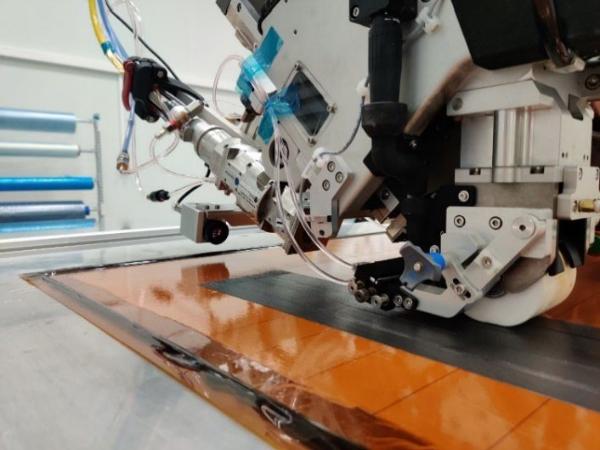

Fibre-reinforced plastics are light, stable and offer many possibilities for lightweight construction, for example in the automotive, aviation or energy sectors. Their strength comes from the combination of lightweight plastic matrices and high-strength fibres, which - like the structure of wood or bone - are optimally aligned along the load paths. However, existing processes for manufacturing these materials are energy-intensive, generate high material losses and require several process steps that often involve unnecessary heating. This is where the Elokofix project comes in with an efficient, continuous process.

The research team wants to make the production of thermoplastic fibre tapes more sustainable and efficient and better exploit the potential of the materials. The researchers are developing a pilot system that enables tapes to be applied endlessly and directly to a substrate. This allows fibre-reinforced components with customised fibre orientation to be produced in a single work step. With an innovative inline splicing unit, the process is designed to avoid material loss by seamlessly joining fibres together during production. At the same time, the system is designed to utilise the existing thermal energy of the process to eliminate the need to reheat the materials. This leads to a significant reduction in energy consumption and CO2 emissions.

The project team is initially developing a dual basic system that can be used to carry out tests as well as map production processes. The processing of spliced fibres should enable uninterrupted operation of the system. To this end, the researchers are developing an adaptive splicing unit and an impregnation tool that ensures high process stability even at splice points. At the same time, the team is designing the splicing module, which will automatically connect the fibres and thus ensure a continuous supply of material. Intensive trials and several adjustments reveal the challenges involved in scaling up the familiar process.

Following successful tests, the researchers want to expand the system to include a direct deposition module. This enables tapes to be applied directly to a substrate without the need for additional heating. The aim of this process is to enable the production and processing of materials in a single step, thereby significantly reducing energy consumption.

At the same time, the researchers are optimising the process parameters of the system in order to maximise the quality of the components.

Ensuring the quality of 3D-printed components: bionic components for aviation

Funding duration:

Start

01.10.20

End

31.07.23

3D printing technologies offer great potential for lightweight construction, as they enable particularly complex and lightweight structures. For example, 3D printing can be used to produce bionic lightweight components for aviation, which can significantly reduce aircraft CO2 emissions. Inline quality assurance is essential for these safety-critical components. This is because the elements have to be closely inspected before they are installed in passenger and cargo aircraft. The problem is that printed parts of the same design can have slight differences.

Traditionally, accompanying samples are produced in the same printing process, which are then subjected to destructive testing. However, it is difficult to transfer the material characteristics of the accompanying samples to the real components due to process fluctuations. The results of the material sample tests can therefore not be transferred one hundred percent to other components. Conventional destructive tests are not an alternative due to the high resource and energy requirements. The same applies to expensive technologies such as X-rays.

In the ENABL3D project, researchers are developing a new method for efficient quality assurance in bionic metal 3D printing. The team aims to reduce the costs of verification by at least 60 percent and the time required for this by at least 65 percent. This opens up new application possibilities, for example in aviation, the automotive industry and medical technology. As 3D printing conserves resources and the bionic lightweight components consume less CO2 during use due to their lower weight, large amounts of greenhouse gas emissions can be saved.

In addition, the method is to be widely used after the end of the project through standards and exchanges with industrial partners.

The project team is developing a testing method with which every single component from the 3D printer can be tested non-destructively. The researchers record the quality properties by intelligently combining indentation testing, process monitoring and micro-computed tomography. To do this, they determine the relevant material properties, such as tensile strength, yield strength, ductility and anisotropy, directly on the component.

Thanks to high-resolution monitoring data, they can verify the process stability and thus transfer the locally measured properties to the overall component. They can also identify any critical areas. Using micro-computed tomography, the researchers can then additionally check the areas classified as critical in a non-destructive manner.

Manufacture forming tools more sustainably: Avoid cold welding with additive manufacturing

Funding duration:

Start

01.08.21

End

31.07.24

The production of forming tools for stainless steel tube processing causes high costs and environmental pollution. Until now, it has required many energy-intensive steps such as vacuum hardening, multiple tempering and a complex physical vapour deposition (PVD) coating. In the PVD process, thin, wear-resistant layers are applied to the workpiece in a vacuum chamber. This improves the surface hardness, but is resource- and energy-intensive.

Another key problem is cold welding during use: During bending, the tube and tool rub against each other, causing metal particles to bond unintentionally. This impairs the service life of the tools and leads to production errors. The research team in the EnERU project is developing a new method to manufacture tools more efficiently and extend their service life.

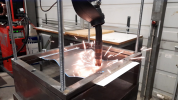

The researchers want to replace the existing coatings with an integrated functional layer. Instead of hardening and coating the entire mould, they are focusing on targeted reinforcement of the stressed areas. They are using the laser metal deposition process (LMD), an additive manufacturing technique. In the LMD process, metal powder or wire is melted locally with a laser and applied in layers. This creates a metallurgically bonded, wear-resistant surface without having to treat the entire mould.

This eliminates energy-intensive steps such as vacuum hardening and tempering. At the same time, material consumption is significantly reduced because the researchers only reinforce the mould where it is actually necessary. The new process should significantly reduce CO2 emissions per mould.

First, the team analyses why the existing tools fail. They measure the loads during the bending process and simulate the forces at work. Based on these findings, they develop new materials that are more resistant to cold welding. They then test different material mixtures and grading strategies in order to achieve a stable transition between the base body and the functional layer.

They then produce prototypes using LMD technology and subject them to practical tests. The new tools have to prove themselves in real bending processes and demonstrate their durability under industrial conditions. Should a tool nevertheless show signs of wear, the LMD process enables a targeted repair in which only the affected area is renewed instead of replacing or recoating the entire tool.

The project is therefore laying the foundations for more efficient, more sustainable production of bending tools. In the long term, the technology could also be used for other forming processes such as the cold forming of aluminium tubes.

Reducing scale formation and material losses: new approaches for sustainable production

Funding duration:

Start

01.04.21

End

30.03.23

Hot forging is a key process for manufacturing high-strength components, for example in the automotive and aerospace industries. In this process, steel is formed at high temperatures of over 950 °C, which leads to the formation of scale. Scale is formed through oxidation and causes considerable material losses of 2-3% of the raw material used. At the same time, scale accelerates tool wear and requires additional process steps such as descaling and cleaning.

The loss of material and the increased effort put a strain on the environment, lead to a high loss of energy for the additional material required and increase production costs overall. At the same time, the demand for lightweight components that combine materials such as steel and aluminium in order to reduce weight is increasing. The technical challenges here lie particularly in the reliable bonding of the two materials, as oxide layers such as scale hinder adhesion.

ERProFit aims to minimise the formation of scale during hot forging. A low-oxygen production environment is intended to suppress oxidation and thus reduce material losses and tool wear. This also enables smooth, high-quality surfaces without additional post-processing. The project team wants to develop new technologies for the hybrid forging of steel and aluminium and thus promote lightweight construction.

By doing so, the researchers want to realise weight savings while ensuring a reliable material bond between the two materials. The project focuses on economically feasible solutions: Instead of costly new buildings, existing production facilities are being adapted to the new requirements through cost-effective retrofits. The team also uses industrial waste gases as a protective atmosphere. This increases sustainability and replaces expensive inert gases.

In the first step, the project partners are developing a concept for creating a low-oxygen atmosphere in the production environment of hot forging. By enclosing the production lines and using industrial exhaust gases, they can significantly reduce the formation of scale. This leads to lower material losses, improved material utilisation and a significant increase in tool life. At the same time, complex descaling processes and additional machining steps are eliminated, which increases the efficiency of the entire production chain.

Thanks to their retrofit concept, the researchers can adapt existing systems with minimal effort and realise sustainable production. The project team is successfully testing the technology under real-life conditions on commercially available forming machines. The results show great potential for CO2 savings: With a production of 500,000 components per year, up to 10,000 kilograms of CO2 can be avoided.

Developing lighter gearboxes for wind turbines: with bionics and innovative sensors

Funding duration:

Start

01.12.20

End

31.05.24

Wind energy plays a key role in the energy transition and is already making an important contribution to German electricity production. In order to achieve the climate targets, the expansion of powerful wind turbines is being driven forward. However, as output increases, so do the dimensions of the turbines, especially the gearboxes, which are key components that require considerable quantities of materials. This increases costs and worsens the carbon footprint of the turbines. In addition, the higher weight of the gearboxes increases the loads on the nacelle and tower, which further increases the material requirements of the entire system.

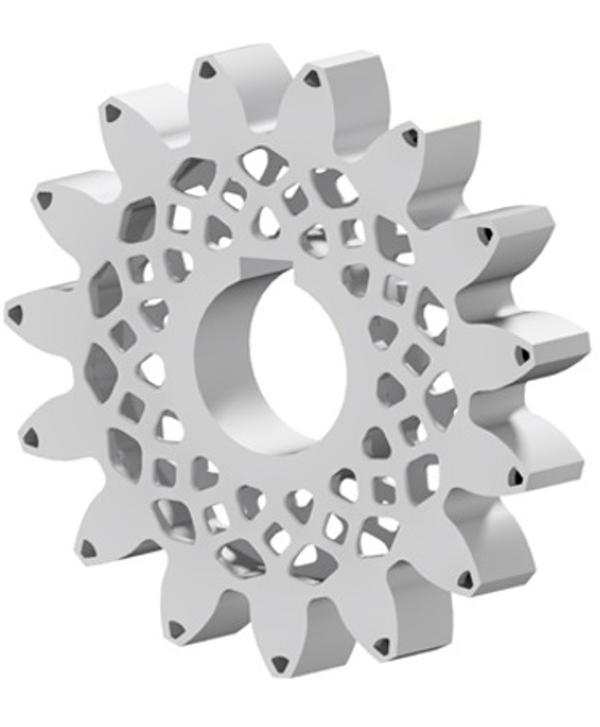

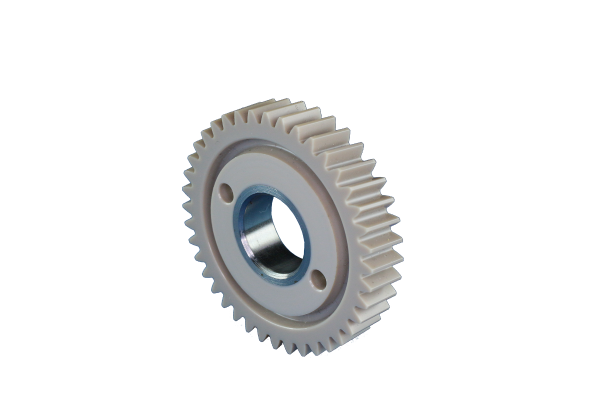

Previous lightweight construction approaches for gears have mostly been limited to the base body and offer weight savings of up to 45 per cent. This is where the FlexGear project comes in with a comprehensive lightweight construction concept: With bionically inspired structures that extend into the gear rims and innovative manufacturing technologies, the researchers aim to achieve weight savings of up to 65 per cent for gears.

The scientists' main goal is to develop a highly optimised lightweight gearwheel with flexible structures. Their approach is based on bionic design principles that minimise the use of materials while maximising stability. The team is not only looking at the gear wheel base body, but also the gear rims, which will enable them to realise additional weight savings.

Another key element is the inside-sensoring system, which is integrated directly into the gear structure. The researchers use this system to record loads and deformations in real time and transfer the data to a condition monitoring system. This enables the proactive compensation of load peaks, which not only increases operational reliability but also avoids the need to oversize the systems. FlexGear thus aims to improve the service life and efficiency of wind turbine gearboxes while reducing CO2 emissions during both production and operation.

Firstly, the researchers are developing bionic designs based on natural models such as diatoms. These microorganisms are characterised by their minimal material structures with maximum stability. Using the ELiSE process (Evolutionary Light Structure Engineering), they develop optimised structures that are flexible enough to compensate for load peaks.

To manufacture the gears, the team uses additive manufacturing processes that enable the realisation of highly complex geometries. This technology also makes it possible to integrate sensors directly into the gearwheel. To this end, the researchers are developing an inside sensing system based on thin-film technology. It measures loads and deformations directly inside the gearwheel and transmits the data in real time to a condition monitoring system that recognises and compensates for critical load peaks.

Finally, the team tests the gears on a specially designed test bench under realistic loads in order to check both their structural properties and the functionality of the sensor system. In order to assess the actual mass savings and mechanical load capacity, the researchers compare the demonstrator with conventional gearwheels. At the same time, the bionic design process is being automated so that the knowledge gained can be transferred to other applications in the future.

Automated production of free-form sheets: Additive processes reduce material consumption

Funding duration:

Start

01.01.22

End

30.04.24

Free-form sheets are indispensable for iconic architectural projects such as the Chrysler Building or the Morpheus Hotel. However, their production is complex: They are usually created using expensive manual labour, as existing processes such as incremental sheet metal forming or multiple-point stretch forming are technically too complex and cost-intensive. Alternatives such as shingles or composite materials require compromises in terms of design and are often difficult to recycle.

At the same time, there is a lack of industrial processes for producing free-form sheets efficiently and in a resource-saving manner. This gap exists despite the increasing demand for lightweight, free-form façade elements that meet high sustainability standards.

The aim of the FORMlight research project is to develop a manufacturing technology that can be used to produce lightweight, rigid, material-pure and recyclable thin sheets for façade construction to replace thick sheets or composite materials such as Alucobond.

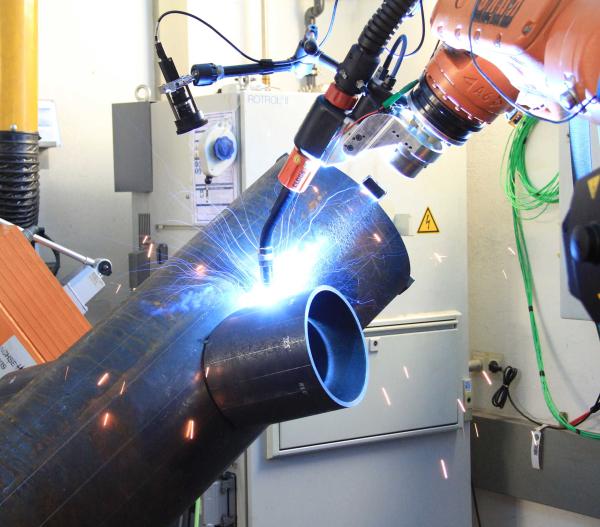

By using Wire Arc Additive Manufacturing (WAAM), an additive manufacturing technology in which welding material is melted using an electric arc as a heat source and applied in layers, both flat thin sheets and elastically deformed thin sheets are to be locally stiffened and frozen in shape by welding on ribs.

This procedure saves material, reduces the weight of the façade elements and should enable the economical production of free-form façade sheets for construction for the first time. In addition to ecological benefits such as CO2 savings and complete recyclability, the FORMlight project aims to create new architectural freedom and revolutionise the construction of free-form façades.

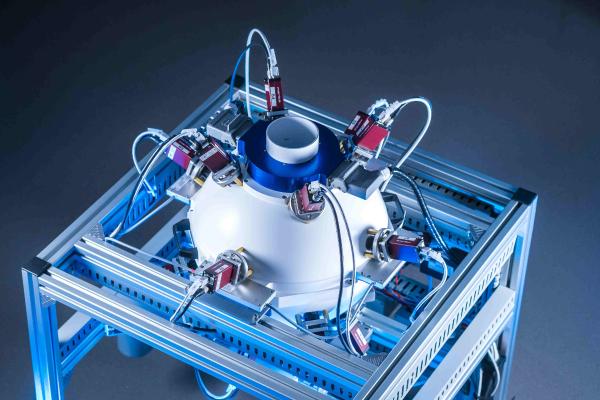

The project team is developing various methods for the digital 3D reconstruction of the reflective metal surface of deformed metal sheets. To do this, the team optically records the deformation of the sheet metal and then converts it into a digital model.

In order to be able to apply the reinforcing ribs to the thin sheets using Wire Arc Additive Manufacturing (WAAM), the team determines the permissible process window experimentally and works on techniques for predicting the optimum arrangement of reinforcing ribs. These prediction techniques are important because the optimum arrangement of the reinforcing ribs depends, for example, on the sheet size, the number of ribs, the sheet deformation and the joint and crossing points of the welding ribs.

In order to derive the required free-form geometries more efficiently from the façade planning, the project team programmed a software tool so that the design of the sheet metal geometries no longer has to be done manually but can be automated. Finally, the team produces a demonstrator from moulded sheet metal with different rib arrangements, which is suitable for presenting the promising technology at trade fairs.

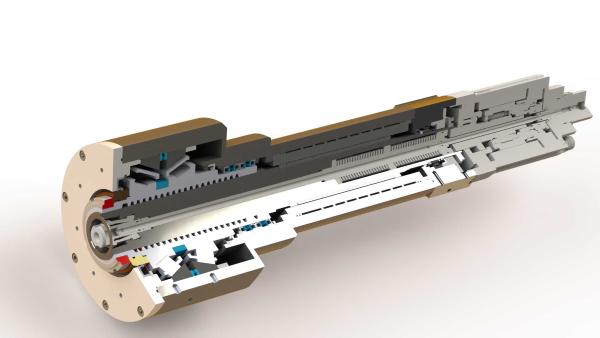

Pultrusion for fibre composites: producing multifunctional lightweight structures

Funding duration:

Start

01.01.21

End

31.12.23

The demands on lightweight structures are increasing: they need to be even lighter, more economical to manufacture and take on additional functions. Fibre composites are ideally suited for this. On the one hand, their mechanical properties open up many fields of application. On the other hand, additional functions can be integrated into these lightweight elements. Just a few lightweight components can fulfil so many technical functions. However, such complex and customised structures cannot currently be manufactured economically in series production, but are instead produced in time-consuming manual work.

The project partners are developing a process to produce multifunctional lightweight structures economically - across all sectors. To do this, they want to use the established technology of pultrusion for fibre composites. Pultrusion means extrusion. This allows continuous fibre-reinforced plastics to be produced efficiently and cost-effectively.

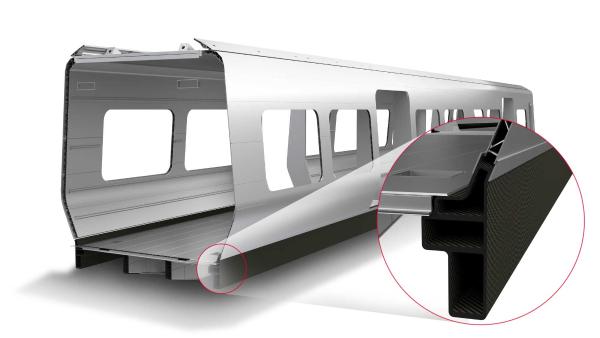

The project team now wants to further develop pultrusion in such a way that both additional materials and electronic components can be integrated into the lightweight structures. The scientists are pursuing two approaches: Firstly, they are developing a mechanically functionalised lightweight profile for rail vehicle construction. The lower vehicle weight can significantly reduce operating and life cycle costs in the transport sector.

Secondly, they are developing sensor-functionalised lightweight construction elements for the rotor blades of wind turbines. These sensor bridges are currently produced manually, with the embroidered strain sensors being processed in a hand laminate. The project team now wants to automate production using pultrusion and ensure mass suitability. The project team then wants to merge the two technologies and thus combine mechanical and sensory functionalisation.

The team integrates metal inserts into the fibre-plastic composites and creates a hybrid layered composite. The inserts act as force transmission or connection points and create additional functionalisation. The components are intended to replace the extruded aluminium profiles in the body of a rail vehicle and significantly increase the degree of lightweight construction while maintaining the same economic efficiency. After optimising the process, the researchers were able to successfully produce several demonstrators. Compared to an aluminium longitudinal beam, they were able to save around 40 percent in weight.

In a second approach, the researchers are integrating strain sensors into the pultrusion process. Their aim is to produce functionalised sensor bridges for wind turbine rotor blades. The sensors recognise overloads and damage at an early stage and have a longer service life. As a result, maintenance intervals and the utilisation period of the turbines can be extended. The team has successfully completed this development and achieved serial production.

To combine the two approaches, the project partners are producing multifunctional profiles for rail vehicle construction by integrating mechanical and sensory functional elements into the manufacturing process. This would further increase the degree of lightweight construction and the condition of the components could be monitored over their entire service life, which would further increase economic efficiency.

Recycling and cleaning plastics: for recyclable battery housings

Funding duration:

Start

01.07.22

Today

09.03.25

End

30.06.25

With the "Green Deal", Europe is aiming to become climate-neutral by 2050. The recycling of plastics, in particular the use of reprocessed plastic waste, known as recyclates, is a key component of this.

Recyclates also play an important role in resource-efficient lightweight construction: the more recycled plastics are used in lightweight components, the more primary raw materials - and therefore CO2 - can be saved.

However, one problem is that conventional mechanical recycling cannot sufficiently break down the material composite. It is unclear whether the shredded material is directly suitable as a recyclate or whether the material composite must be completely broken down.

The researchers are using a high-voltage battery housing to investigate how recyclable battery housings can be manufactured. These housings are crucial for the protection of sensitive vehicle batteries and must therefore fulfil high safety requirements, for example in the event of side impacts and underride protection.

They are part of the vehicle's load-bearing structure and must bear a surface load of up to 500 kg through the battery modules. They also integrate complex functions such as battery cooling.

The project team is investigating ways to make battery housings recyclable and recyclable. The researchers are relying on the new adaptive recycling technology CreaSolv®, which uses solvents to recycle and clean plastics. This technology already enables the recycling of thermoplastic films.

The team is now working on transferring this method to the recycling of lightweight fibre composite structures, i.e. engineering plastics. The researchers are analysing the entire life cycle of a fibre-reinforced plastic battery housing across all stages of the value chain.

They are investigating the production and processing of the material, its ageing in use and the possibilities for recycling it so that it can ultimately be used again in the same component. With the prototype developed, the research team wants to demonstrate that the greenhouse gas-intensive primary plastic can also be replaced by recycled material for sophisticated components for electromobility.

Making particle foams more sustainable: Process energy-efficiently, enable recycling

Funding duration:

Start

01.12.20

End

31.05.24

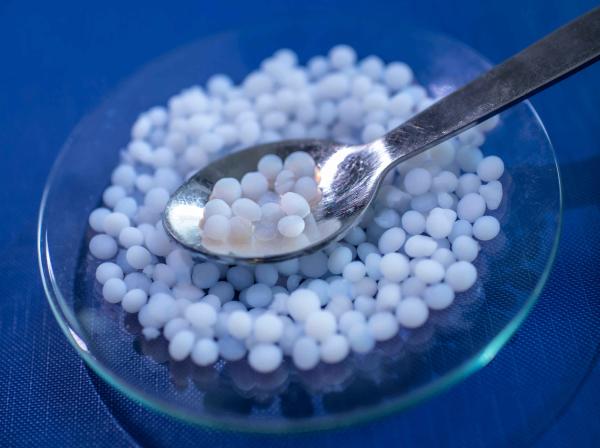

Particle foams such as expanded polypropylene (EPP) are key materials for lightweight construction. In the automotive industry in particular, they help to reduce vehicle weight and thus lower fuel consumption and CO2 emissions. However, traditional production using hot water vapour is very energy-intensive. Only around one per cent of the energy is used for welding the particles, the rest is lost unused.

At the same time, the recycling of EPP material is not yet sufficiently realised. At the end of its useful life, the material is usually thermally utilised. A genuine circular economy is not yet possible, as the processing of recycled material impairs the quality. This is where the GePart research project comes in: The team wants to improve processing and close the material cycle of EPP sustainably.

The GePart project team is pursuing two key objectives: developing an energy-efficient processing technology and increasing the proportion of recycled material. With the help of radio frequency (RF) technology, the researchers want to weld EPP without water vapour in the future. This saves up to 90 per cent energy, as the heat is generated directly inside the foam beads. At the same time, the scientists want to increase the proportion of recycled EPP material to between 50 and 70 per cent. To achieve this, the project team is further developing the recycling processes and precisely analysing the material properties. The aim is to optimise the quality of recycled EPP so that it meets the requirements for series production.

In order to industrialise RF technology for EPP, the researchers are further developing the process at laboratory level. In doing so, they are able to confirm the advantages of RF technology over vapour-based processing: uniform heating, minimal energy loss and the use of cost-effective plastic tools. At the same time, the team is developing new recycling strategies to reprocess EPP material to a high standard after its utilisation phase.

The scientists are analysing the degradation behaviour of the material along the cycle and optimising the processes for removing impurities. Comprehensive tests have shown that a recyclate content of up to 70 per cent is realistic without compromising the quality of the components. An accompanying life cycle assessment confirms the successes: 15 per cent energy savings in production and 25 per cent less CO2 emissions through the use of recycled material.

Reusing aluminium scrap in cars: Focus on recycling and material sorting

Funding duration:

Start

01.07.21

End

30.06.24

Sustainable lightweight materials are crucial to reducing the environmental impact of mobility and increasing resource efficiency in the industry. Manufacturers are increasingly using aluminium, especially in highly stressed components such as axle components, wheels, body structures or high-voltage battery housings, as it is significantly lighter than steel, for example, and can therefore significantly reduce CO2 emissions during the use phase. However, aluminium production is not only expensive, but also releases a lot of CO2.

One sustainable option is to recycle aluminium. The use of secondary aluminium is not only sustainable, it also pays off for companies. By analysing and optimising the digitalised process chain, the researchers are increasing cost efficiency, for example by adjusting the alloy composition or the forming processes. In this way, lightweight components based on secondary aluminium can be brought into widespread industrial use, for example in mid-range vehicles or aircraft.

In the Green-AL-Light research project, a broad-based consortium is investigating how aluminium from car scrap can be recycled and reused. To this end, the project partners are looking at the entire process chain, starting with the recycling of the cars and the sorting of the end-of-life (EoL) scrap materials. This is followed by the development and testing of new secondary wrought alloys, casting of the alloys with the highest possible secondary aluminium content, processing into components by extrusion and / or forging and testing for use in cars. To ensure that the holistic analysis is successful, the scientists are building up the individual steps in a cross-location and digitally networked manner. They cover all stages of the process chain. The interdisciplinary team aims to demonstrate that EoL material can also be used for highly stressed aluminium components and can be used cost-effectively.

In order for the secondary aluminium to be reused, the EoL scrap must be reliably separated by type and alloy. To this end, the project team is further developing the sorting technology using the laser-induced breakdown spectroscopy (LIBS) process. Among other things, the project partners are investigating whether, and if so, in what quantity, previously undesirable by-elements are contained in the recycled material. This enables them to subsequently adapt and optimise the composition of the alloy.

By reusing EoL scrap in high-quality aluminium alloys, the material cycle is closed. This conserves resources and reduces CO2 emissions. Using the example of an aluminium forged wheel from Audi, the project partners calculate a potential saving of at least half the CO2 compared to a wheel made from primary aluminium. In addition, the increased use of secondary aluminium results in less waste that is problematic to dispose of, such as red mud.

Making cold forming more resource-efficient: digital in-process testing

Funding duration:

Start

01.05.21

End

31.12.24

A large proportion of CO2 emissions are caused by industrial production. Optimised production processes - for example in automotive or mechanical engineering - therefore offer great potential for reducing emissions.